process

SUPPLY CHAIN SERVICE SOLUTIONS

Production Procedures

Forward-thinking from well made product

Apollo has the competitive edge of sourcing and high quality development capabilities of Cosmetics Packaging and Household Goods of plastic.

From product ideas, design, molding, production to logistics, we provide a total solution for products that customers want and need.

In addition, we provide high quality products that meet the customers’ standard through continuous change and innovation.

From product ideas, design, molding, production to logistics, we provide a total solution for products that customers want and need.

In addition, we provide high quality products that meet the customers’ standard through continuous change and innovation.

-

Customer

Request & design -

R&D

-

Molding

-

Injection

-

Post processing

-

Production &

Assembly -

Quality

Management -

Logistic

01

Product Planning and Design

- 14days

Product Planning and Design

Conception & design

The design team members of Apollo Industrial operate a differentiated process to create a product with various ideas and know-how to meet the continuous future values and customers needs. In addition we provide creative products and ideas by analyzing trends and customer’s needs.

Idea Conception Sequence

The Design Planning Process

Design Follow up

-

Research

-

Brainstorming

-

Idea Sketch

2D Rendering -

3D Modelling

Mock-up Sample.

Design Achievements

DESIGN ACHIEVEMENTS

Certificate of Trademark Registration

- Curalab

- Apollo+Beauty, Living, Farm

34Cases

Certificate of Design Registration

- Twist Mist, Essence

- Push Type Of The Foaming Pump

84Cases

Good Design

- 2018 Monosil

- 2003 Leaf Shape Of The Bottle

2Cases

02

R&D

- 35days

R&D

R&D

The R&D team member of Apollo Industrial operates R&D center for development and supply of technology, high-quality products and customized products based on the high quality professionals capable of precise and micro-structure design. In addition, through professional knowledge of molds, we design and develop productive products by reviewing problem solving, and functionality of the product.

Lab Advantages

R&D center’s core characteristic and strength

-

Structure Design precise micro structure

-

Stability Review continues stability

-

Funtionality professional technical skills

-

Injection analysis analysis injection molding’s program

The R&D team member of Apollo Industrial strives to investigate the technology development by continuous study.

R&D Achievements

R&D ACHIEVEMENTS

Patent

- Capable of discharged multiple contents in once

- Mechanism of trigger

- push function of the head.

Certificate Of Utility Model Registration

- Dispenser Pump For Liquid Bottle.

Technical Copyright

- The Locking Mechanism Of Trigger

- Pressing Bottle Foam Generator

03

Mold Development

- 45days

Mold Development

Molding

Since 1976, with the accumulation of technologies, we handle the process of the product developments such as design, prototype, and mold production through maintaining an optimized environment and manage to maintain the mold operated by Apollo and partner companies for deploy by an immediate production environment.

Production facility

Production facility

-

Machine Clean environment for high precision processing of molds

-

Milling Milling the plane and curved surfaces

-

Computer Numerical Control Control product with digital control machine

-

Cutting Machine Machine the gap of the stepped area and keep a certain distance during machining

-

Conta Cutting Machine Cutting Wood, Aluminum, Steel

Based on accumulation research, became a trustworthy partner.

04

Injection Molding Department

- 12days

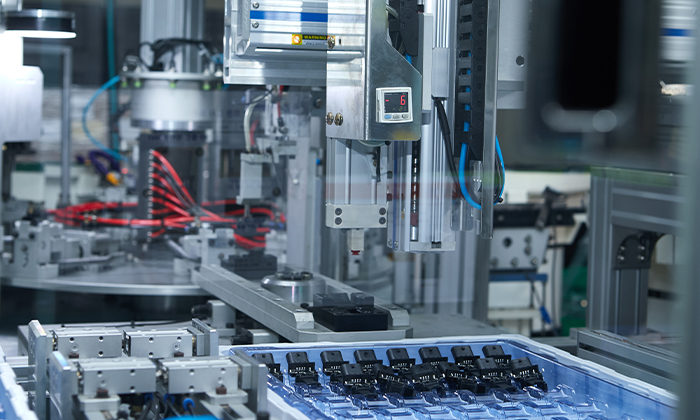

Injection Molding Department

Injection

Installed automatic injection robots and conveyor belts for each of injection molding machine to avoid scratches and contamination. Operating the latest high-function facilities with excellent precision, and operates a separate facility maintenance team consisting of engineers with accumulated experience and technology to institutionalize regular inspections and preventive inspections, providing the basis for perfect product production in an optimal environment.

Features

Features

-

01Managing Clean-RoomManaging clean room at the injection site to avoid any quality issue during production.

01Managing Clean-RoomManaging clean room at the injection site to avoid any quality issue during production. -

02Continuously Invest facilityIn order to increase the completeness of injection, investing facility

02Continuously Invest facilityIn order to increase the completeness of injection, investing facility -

03Monitoring System In Production SiteManage all injection equipment by using production monitoring system in production facility

03Monitoring System In Production SiteManage all injection equipment by using production monitoring system in production facility -

04Smart FactoryCurrently, aim to operate the smart factory with upgrading second stage.

04Smart FactoryCurrently, aim to operate the smart factory with upgrading second stage.

Lab Advantages

Lab Advantages

-

0192,000,000Units/year*Dispenser Pump

Oil Pump

Essence Pump -

0216,000,000Units/year*Mist Spray

Perfume Spray

Inverted Spray -

0334,000,000Units/year*Foaming Pump

Foaming Pump w

Applicator -

0426,000,000Units/year*Form Type

Spray Type

Foam/Spray Type

Operating 25 electric injection machines and 38 hydraulic injection machines

in the production sites

in the production sites

Operating two shifts from Monday to Friday in accordance with the Labor Standards.

05

Purchasing Department / Post-Process

- 14days

Purchasing Department / Post-Process

Post processing

Qualified manufacturing and sourcing all domestic and foreign plastic product, and provide total solution including mold development, manufacturing, post-processing and assembly. In addition, we propose all areas of plastic post-processing according to the characteristics of the product to meet customer’s request.

Post processing list

Post-Process’s List

-

01PlatingAvailable various shapes, patterns, printing and post-process

-

02IR PrintingImprove print’s durability, High Level of the Color’s Implementation

PP/PET/PETG/ABS/SAN/PN -

03UV Silk PrintingHigh Level of the Color’s Implementation, Variety range of dose improves the high quality

PP/PET/PETG/ABS/SAN/PN -

04UV Silk Printing / HalftoneHigh Level of the Color’s Implementation, Variety range of dose improves the high quality

PP/PET/PETG/ABS/SAN/PN -

05UV Silk Printing / Flame Treatment / Hot StampingImprove Printing’s Adherent (Flame Treatment / PP,PE), Variety range of dose improves the high quality, implement various hot stamping (thickness, fonts, pattern, colors)

PP/PE -

06LabellingAvailable label including the various type of the printing and post-process

PP/PET/PETG/ABS/SAN/PN -

07Glossy CoatingAvailable the various level of the transparency

PP/PET/PETG/ABS/SAN/PN -

08Gradation Matt CoatingAvailable Gradation Coating

Available the various level of the transparency

PP/PET/PETG/ABS/SAN/PN -

09Gradation Glossy CoatingGradient Coating

Available the various level of the transparency

PP/PET/PETG/ABS/SAN/PN -

10Matt Coating / PearlAvailable the various level of the transparency

PP/PET/PETG/ABS/SAN/PN -

11Metal CoatingAvailable the metal color’s coating (Pearl, Metal)

PP/PET/PETG/ABS/SAN/PN -

12SF CoatingSoft Fell Touch 구현을 위한 특수 코팅

PET -

13Matt Vacuum MetallizationAvailable Multiple Color

Implementation after Deposition

PP/PET/PETG/ABS/SAN/PN -

14Glossy Vacuum MetallizationAvailable Multiple Color

Implementation after Deposition

PP/PET/PETG/ABS/SAN/PN -

15ShrinkingAvailable various forms of shrinkage

Available various type of material, printing and post-process

PP/PET/PETG/ABS/SAN/PN -

16Hot-StampingAvailable the various type of hot stamping such as thickness, fonts, pattern, color

PP/PET/PETG/ABS/SAN/PN -

17Matt Hot-StampingAvailable the various type of hot stamping such as thickness, fonts, pattern, color

PP/PET/PETG/ABS/SAN/PN -

18Thermal Transfer PrintingAvailable Multiple Fonts and Shape

( ex : wood, ston)

PP/PET/PETG/ABS/SAN/PN -

19AL Color Eetal WorkAvailable Multiple Fonts and Shape

Printing, Post-processing, Hairline -

20Laser CuttingAvailable Multiple Fonts and Shape with Laser Cutting

PP/PET/PETG/ABS/SAN/PN

06

Automation Production Facility And Assembly

- 15days

Automation Production Facility And Assembly

Production & Assembly

By building an optimal production system, we are capable of production from small-volume to mass and provide timely supply the best quality management for customer’s point of view. We always produce the best products through the best manufacturing system with our customers.

Facility

Facility

-

01Running Clean Room In PlantOperating clean rooms at the injection sire to avoid any issues during production.

01Running Clean Room In PlantOperating clean rooms at the injection sire to avoid any issues during production. -

02Separated Assembly and PackagingOperating separated assembly and packaging line

02Separated Assembly and PackagingOperating separated assembly and packaging line -

03Automatic Speed DoorAvoiding the contamination, automatic speed doors were installed.

03Automatic Speed DoorAvoiding the contamination, automatic speed doors were installed. -

04Air shower-roomPreventing the contamination, the air shower rooms were installed at the entrance of the facility

04Air shower-roomPreventing the contamination, the air shower rooms were installed at the entrance of the facility

Production Capacity

Production Capacity

Installed 53 automatic inspection machine and 6 semi-automatic inspection machine

Operating two shifts from Monday to Friday in accordance with the Labor Standards.

Operating two shifts from Monday to Friday in accordance with the Labor Standards.

-

Dispenser Pump36,432,000

-

Essence,Oil,Remover5,544,000

-

Mist,Perfume15,480,000

-

Trigger4,752,000

-

Foaming21,516,000

-

2/3.5cc Pump8,052,000

Total

81,216,000

(1 Year / Unit Standard : ea)

Features

Features

-

Automatic production systemApplying 45 years of technology know-how45years of Technology Know-How

-

Top Cosmetic Pump and Spray ManufacturerTop production ability among domestic cosmetic pump and spray manufacturersTop Production Ability

-

Major Pump’s ManufacturerEstablished four major types of the pumps such as foaming, dispenser, mist, and trigger’s production linesFoaming, Dispenser,

Mist, Trigger -

Maximum production of mist pumpsWe produce mist products, which are the basic mechanism of perfume pumps.15,480,000production

07

Quality Assurance

- 10days

Quality Assurance

Quality Management

Aiming zero defect rate through skillful and meticulous inspection, manages the top of the quality with accumulated technologies, abundant human resources and know-how.

Certificate

Certificate

Keeping systematic quality guarantee system through certified ISO 9001, 14001, 15378 and CGMP 22716

Quality Applications

Quality Test Equipment

-

Constant Temperature ChamberTest Of Constant TemperatureChecking functional OK/NG test at constant temperature for a long time

-

DepressurizerLeakage Test-Checking leakage test with filling the product with distilled water in the depressurizer chamber

-

Scale InstrumentChecking Dosage TestChecking the exact amount of the dosage with scale instrument

-

Push Pull GaugPress Pressure Test, Removal TestChecking pressure when pressing the head of the pump, removal force when opening the over-cap, removal force when removing hose or head.

-

Cam ScottMicroscope & Measuring SizeEnlarge the product and measure the dimension of the small component.

-

Pumping Test InstrumentPumping Reliability testThe continuous pumping issue needs to be checked frequently whenever pump faces issue.

-

Torque Test EquipmentApplication Torque / Removal ForceRotate the shoulder part of the pump and measure the application torque and over-cap removal torque

-

Vernier CalipersMeasuring The ScalesMeasuring Product’s Scales

Puality Shipment procedure

The Procedure Of Quality Inspection

Recently Apollo implemented a concept of smart factory, supply delivery on time from small volume to massive production part and best manufacturing quality control for the customer’s characteristics

-

01Injection Molding

-

02Inspection Of Subsidiary Materials

-

03Assembly Of Semi-Finished products

-

04Inspection Of Semi-Finished Products

-

05Assembly Of Automatic Lines

-

06Functional Inspection

-

07Process Inspection

-

08Total Appearance Inspection

-

09Package

-

10Final Inspection, Delivery

08

Logistics & Delivery

- 5days

Logistics & Delivery

Logistic

Based on a systematic logistics management systems, delivery products on time covering metropolitan area and thoroughly practices customer first management policies that supply in a timely manner.

Production facility

Production facility

By systematizing its logistic system, trying to ensure that products are delivered to customers quickly